The Key to Product Purification: Effective Separation Techniques

Types of Distillation for Product Purification:

Fractional Distillation: Separates components with similar boiling points, ideal for complex mixtures.

Vacuum Distillation: Reduces boiling points, suitable for heat-sensitive substances.

Batch Distillation: Processes a fixed quantity of liquid in a single operation.

Continuous Distillation: Processes a continuous stream of liquid, often used in large-scale production.

Benefits of Product Purification:

Improved Product Quality: Removes impurities and contaminants, enhancing product performance and appearance.

Enhanced Safety: Ensures products meet safety standards and are free from harmful substances.

Regulatory Compliance: Adheres to industry regulations and standards, avoiding legal issues.

Increased Shelf Life: Reduces product degradation and extends its shelf life.

Cost-Effective: Can be more cost-effective than other purification methods in certain applications.

Applications of Product Purification:

Pharmaceutical Industry: Purification of active ingredients, solvents, and intermediates.

Chemical Industry: Production of high-purity chemicals, solvents, and intermediates.

Food and Beverage Industry: Concentration of juices, production of alcoholic beverages, and flavor extraction.

Essential Oils: Extraction and purification of essential oils from plants.

Research and Development: Laboratory experiments and analysis.

Choosing the Right Separation Method:

Consider Product Properties: Evaluate the boiling points, viscosities, and chemical properties of the substances to be purified.

Determine Desired Purity: Define the required purity level of the final product.

Assess Scale of Production: Determine whether a small-scale laboratory setup or a large-scale industrial system is needed.

Evaluate Energy Efficiency: Consider the energy consumption of different distillation methods.

At RTL Engineers, we make product purification a breeze! Whether you're refining chemicals, food ingredients, or pharmaceuticals, our cutting-edge process engineering solutions ensure your products are pure, safe, and ready for market. We use advanced filtration, separation, and distillation techniques to remove impurities with precision and efficiency. Think of us as the clean-up crew for your production line—only faster, smarter, and way more fun to work with. Purity isn’t just a goal; it’s our promise. Trust us to deliver crystal-clear results that boost quality, compliance, and customer satisfaction. Let’s purify your product—and your process!

Key Product Purification Capabilities:

Filtration Systems – Microfiltration, ultrafiltration, and nanofiltration for solids removal and liquid clarification

Distillation Techniques – Fractional, steam, and vacuum distillation for high-purity separation

Crystallization Processes – Controlled solid formation for pharmaceutical and specialty chemical applications

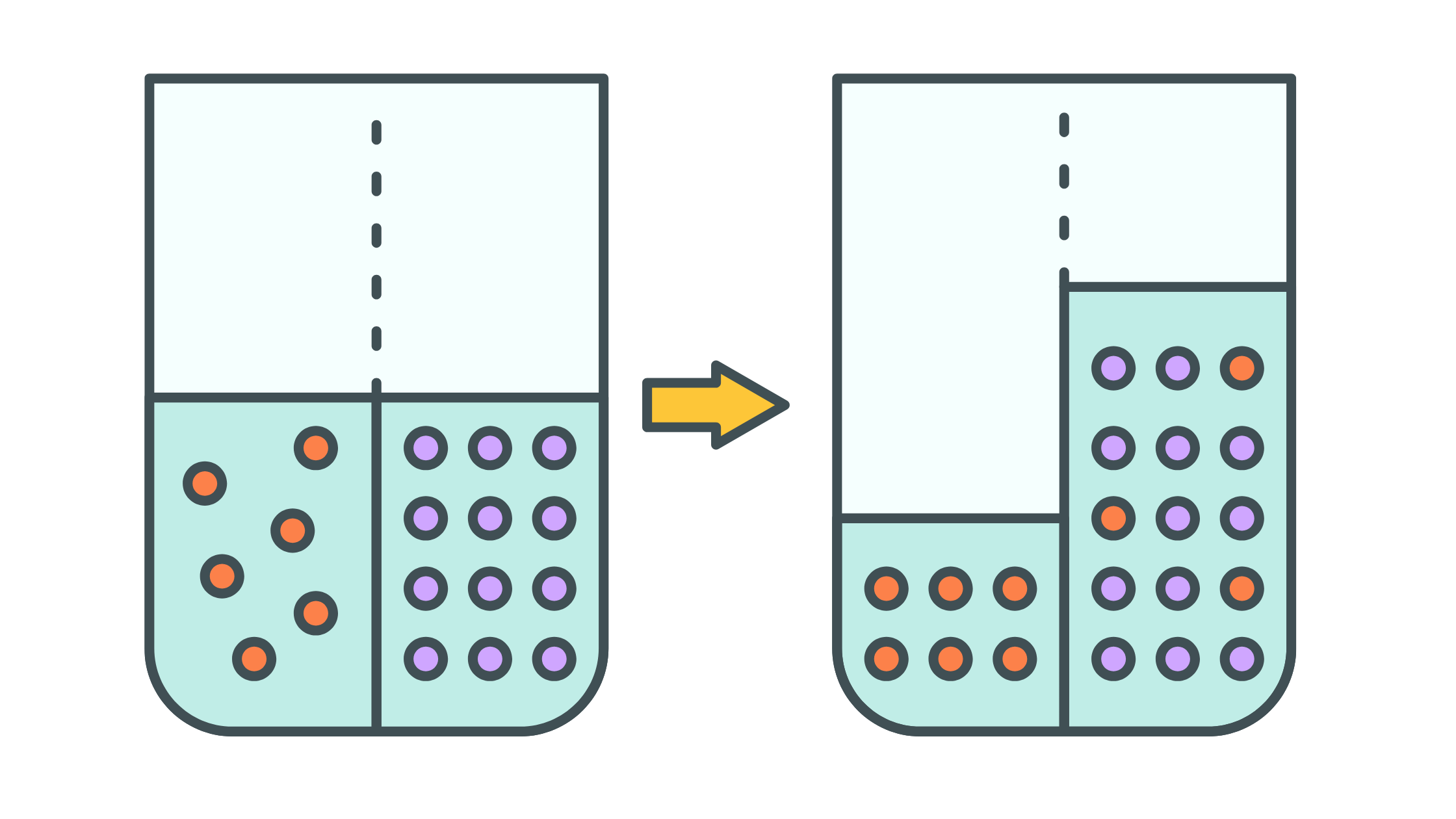

Liquid-Liquid Extraction – Efficient separation of compounds based on solubility differences

Membrane Separation – Advanced membrane technology for selective purification

Adsorption and Ion Exchange – Removal of trace impurities, colorants, or metal ions

Solvent Recovery and Recycling – Eco-friendly purification and cost-saving solutions

Custom Purification System Design – Tailored solutions for batch or continuous operations

Boost product quality, streamline production, and meet stringent industry standards—all with the power of expert product purification in process engineering. We also offer other applications and processes for your next big project!